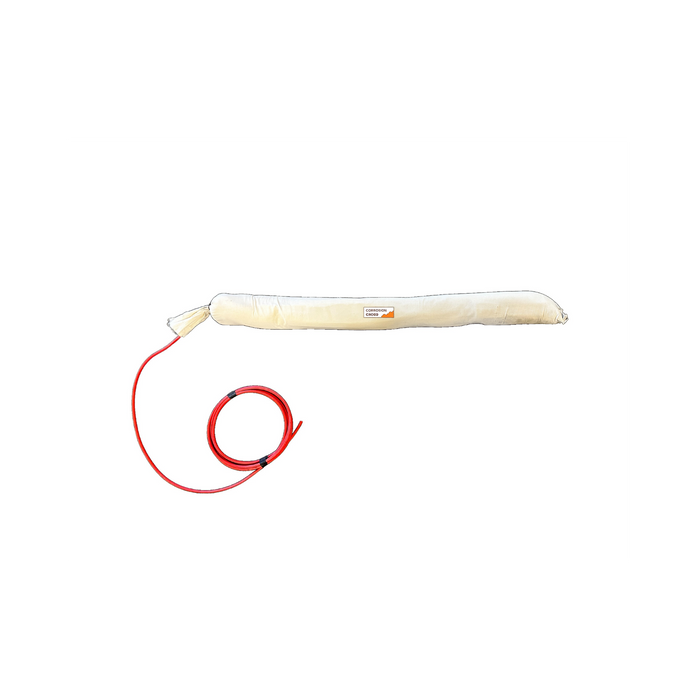

Zinc Anode Bag 15 Lbs, for Below Ground use, Similar to widely Known 12S1.4ZP & ZT 1144-2

Article: 33002

Original part number: 12S1.4ZP & ZT 1144/2

American Society for Testing Materials (ASTM) Standard B843

The backfilled anode prevents corrosion on your storage tank and on cables below ground. By applying cathodic protection, we extend the service life of these metal components. If you have any questions, please consult the product description and FAQ below, or contact us directly.

| PCS | Discount | Price |

|---|---|---|

| 2 | 5 % | 5,330.69 kr /pc |

| 5 | 10 % | 5,050.13 kr /pc |

| 20 | 20 % | 4,489.00 kr /pc |

| 50 | 25 % | 4,208.44 kr /pc |

Product description

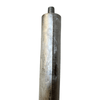

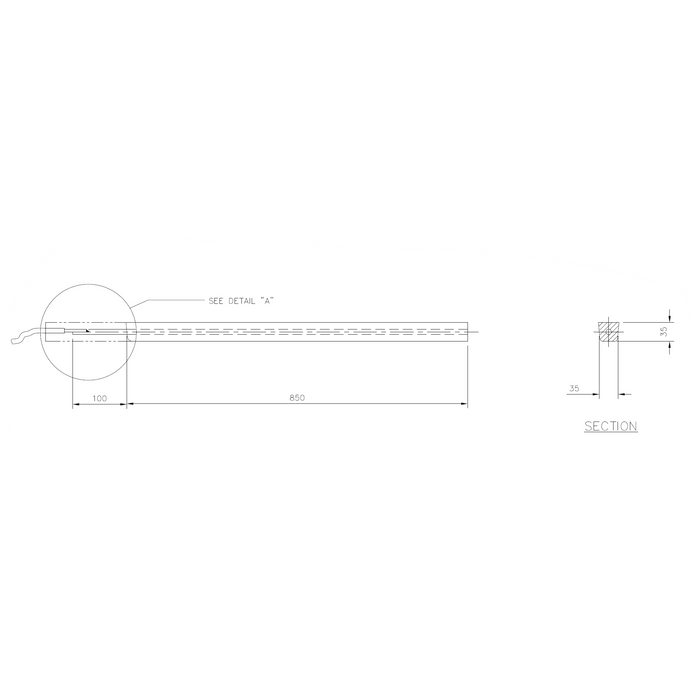

The efficiency of our zinc anode is about 95%, -1100mV rel CU / CUSO4 electrode (US MIL 18001K). These anodes are normally used in sea or brackish water or in soil and usually not in the case of resistivities in excess of 15Ωm. The anode comes with a 5m cable type XLPE / PVC 6mm2 red in backfill of bentonite. The cable connection is embedded in epoxy or equivalent. Power delivery in 10Ωm earth is about 28mA

Korrosionsgruppen’s pre‑packaged Zinc Anode ZT 1144-2—also known as a sacrificial zinc anode rod or ground‑bed bar—delivers reliable, maintenance‑free cathodic protection for steel pipelines, storage tanks, marine piles, jetties, offshore structures, and grounding systems. Manufactured in Sweden from high‑purity MIL‑DTL‑18001K zinc alloy and pre‑encased in sodium bentonite backfill, this ready‑to‑install anode provides up to 5.45 kAh of electrochemical capacity and maintains a stable −1.10 V (Cu/CuSO₄) potential, mitigating galvanic corrosion in seawater, brackish water, and soils up to 15 Ω·m (1 500 Ω·cm) resistivity. A robust 6 mm² (≈ AWG 9) XLPE/PVC lead cable is epoxy‑potted for leak‑free performance, while the compact 850 mm / 33.5 in profile simplifies shipment and trench placement. Use Korrosionsgruppen anodes to extend the service life of critical assets with a cost‑effective, sustainable zinc cathodic protection solution.

FAQ

**Q: How long does an anode bag last?**

**A:** Under optimal conditions, our anode bags can last for up to 5 years. Service life may vary with environmental factors, including the aggressiveness of the surrounding soil or water. Regular inspections help assess the bag’s condition and remaining life.

**Q: How do you install an anode bag for a propane tank?**

**A:** Installation involves several steps:

1. Clear the area around the tank.

2. Excavate a hole near the tank and place the anode bag inside.

3. Connect the bag to the tank using the designated cable, ensuring a firm, secure bond.

4. Backfill the hole, making sure the anode bag remains in full contact with the surrounding soil.

**Q: What are anode bags used for?**

**A:** Anode bags provide cathodic protection. They safeguard various metal structures—such as propane tanks, underground pipelines, buried steel assets, docks, piers, and fire hydrants—against corrosion. By producing a small electric current, anode bags counteract the corrosive electrochemical activity that leads to rust and deterioration.

**Q: What is an anode bag?**

**A:** An anode bag is a type of sacrificial anode used in cathodic protection systems. It is a bag filled with a reactive metal—typically magnesium or zinc—connected to a metal structure to shield it from corrosion. When placed in soil or water near the structure, the bag generates a protective electric current that prevents the metal from corroding.